Master Tube Cleaning Brushes: A Guide to Varieties, Uses, and Finding the Perfect Match!

/0 Comments/in Blog, News /by BolexbrushBlocked pipes are trouble to the homeowners but it is not only chemical solutions to the problem.

All kinds of blockages can be cleared using simple, non-invasive tools like tube cleaning brushes.

What are Tube Cleaning Brushes?

Tube cleaning brushes are tools often used to clean the interior of pipes, ducts and any other hollow instruments. They have thin and cylindrical metallic structures constructed from brass or stainless steel to enable the insertion of the body into pipes. These flexible bodies can flex around curves in order to get to all areas that require cleaning.

Tube brushes are available in different sizes depending on the pipe diameter, which can be as small as a few millimeters or as large as several centimeters. The size refers to the pipe dimension it is meant to clean, and it is the size of each brush.

Types of Tube Cleaning Brushes

Twisted-in-Wire Brushes

Twisted Wire Brushes are made of twisted wire which forms the core of the brush. Wire coats like nylon, brass, or stainless steel are then spiraled around the wire to make the bristles. These are strong and designed for cleaning slender pipes.

Nylon Tube Brushes

Nylon Tube Brushes contain nylon filaments hence softer than the metal Bristle brushes. They are best used on smooth items such as plastic tubing where there is no need to spoil the surface.

![]()

Stainless steel tube brushes

These brushes have stainless steel bristles and are ideal because they are rigid and durable. They offer very good scrubbing action. They are especially suitable for cleaning up rough and hardened deposits or greases.

Brass Tube Brushes

Brass bristle brushes are very stiff, long lasting brushes. However, they are softer than stainless steel so they do not scratch metal surfaces but they can clean off hard stains. These brushes are appropriate for cleaning small metal pipes.

Applications of Tube Cleaning Brushes

Cleaning pipe, hose, tubing inside – Tube cleaning brushes are widely used to clean the pipes in order to eliminate scale, rust, dirt, and blockages. It can be used for removing wastes from heating and cooling systems as well.

Cleaning medical equipment – Fiberscopes and other long slender flexible medical instruments have small diameters and need fine brushes to clean their lumens. Internal cleanliness is very important to ensure that there is no hindrance to the smooth running of affairs and to avoid the spread of infectious microbes.

Cleaning guns/firearms – The bore brush can be used to clean the interior of the barrel chambers for guns. It is also important to maintain cleanliness of barrels to facilitate accurate functioning.

Automotive uses of tube brushes – Specialized tube cleaning brushes are used to clean hard to reach areas in carburetors cylinders, radiators among other automotive sub-assemblies to remove debris that impairs their efficiency.

Cleaning laboratory/scientific equipment- Tube cleaning brushes are used to clean test tubes, vials, and even the inside of expensive scientific instruments.

Cleaning food processing equipment – Due to the specialized designs, cleaning of internal sections of pipes, tubing and fillers used in the preparation of food items like beverages and dairy products can be done effectively using tube brushes. Sanitation is paramount and must be observed to the letter.

If you are looking for good quality tube cleaning brushes, Bolex Brush must be your ultimate destination. Bolex Brush provides different types of tube cleaning brushes that fit your daily house-hold as well as industrial cleaning needs. Visit us to know how we can help you!

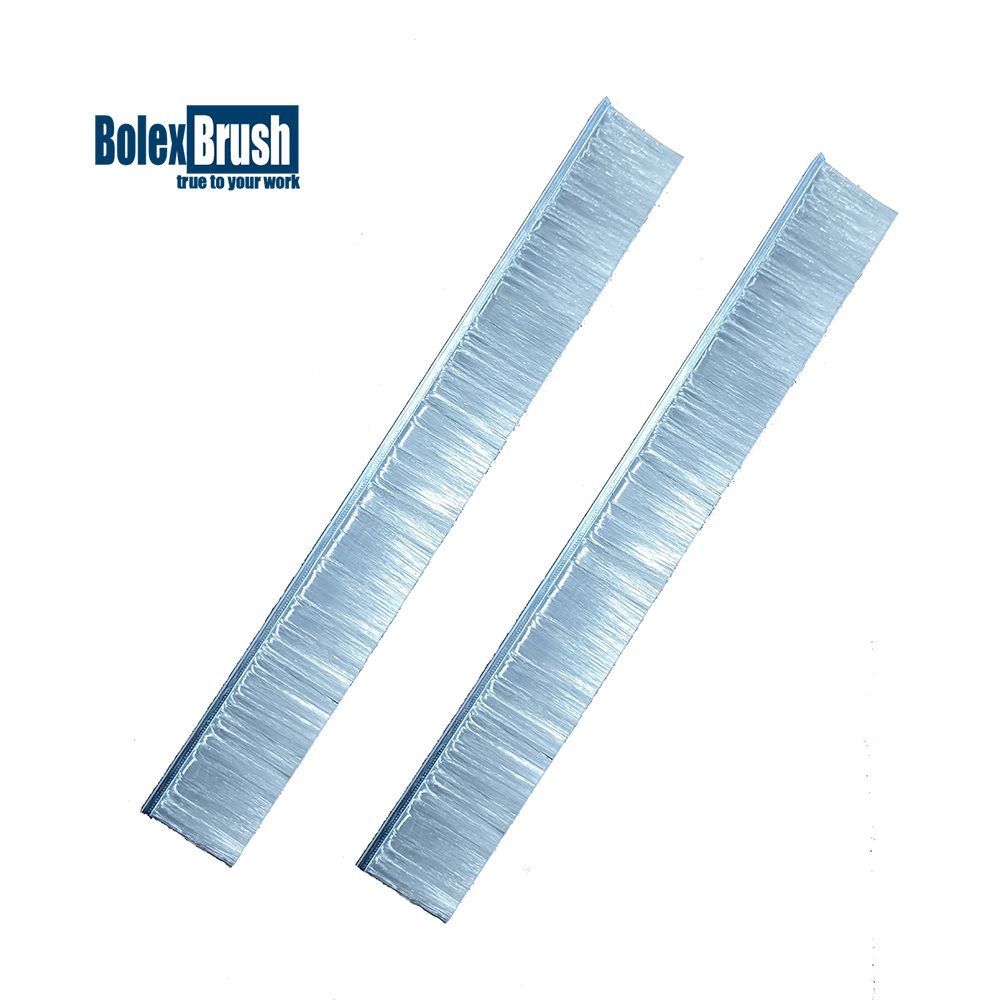

The Impeccable Strip Brushes For Durability And Versatility

/0 Comments/in Blog, File, News /by BolexbrushThe strip brush is one of the most versatile brushes in the industry, with wide applications in sealing, cleaning, and protection. Starting with manufacturing and automotive to household applications, their benefits vary drastically, making them rather an integral part of almost all processes.

Sealing Effectively

One of the main applications of strip brushes is sealing gaps and openings in doors, windows, and equipment. This blocks out dust, dirt, and air drafts, thus improving insulation and helping in energy cost savings. Strip brushes serve as very good cleaning tools, especially for areas that are difficult to reach by conventional methods. The strip brushes serve to efficiently sweep away dust, dirt, and other particles from machinery, conveyor belts, or even sensitive surfaces. It is also used in the industry for cleaning moving parts to ensure their smooth operation and to minimize downtime from clogging up or malfunctioning.

Durability and Long Life

The brushes would hence be very efficient for multiple uses even in conditions that are adverse, like heat, chemicals, or any other abrasive elements. This particular aspect makes these brushes very economical since they can withstand harsh conditions without necessarily compromising performance.

Strip brushes, in an industrial or mechanical setting, could be used as a barrier to foreign particles getting inside sensitive areas or machinery. This prevents not only damage to equipment but also adds safety from the chances of accidents due to debris or contamination.

Strip brushes can be customized to nearly any demand for length, density, and type of bristles, making them suitable for everything from applications in weatherproofing up to cleaning conveyor belts. Strip brushes fulfill the needs for many quite effective seals, cleaners, and protective functions throughout industries because of product longevity and flexibility in design to suit specific purposes. Go ahead! And claim the top benefits of the strip brushes for the best experience and vibes.

The Significance Of The Tube Cleaning Brushes that You Must Know

/0 Comments/in Blog, File, News /by BolexbrushTube cleaning brushes have definitely got to be among the most vital tools in preserving cleanliness and efficiency across the spectrum of industries, commercial establishments, and laboratories. Their specially crafted design allows them to clean out tubes, pipes, and other cylindrical objects from the inside effectively.

Long tube cleaning brushes reach deep into tubes and pipes to clean their inner surfaces. In this design, the bristles are radially spaced around a flexible core and permit full contact with the inner walls, efficiently removing built-up residues, debris, and contaminants. This ensures overall cleanliness for the upkeep of performance and hygiene of concerned systems.

These tube-cleaning brushes come in various sizes and diameters to fit the dimensions of tubes and pipes. This makes them quite useful, ranging from very small laboratory tubes to big industrial pipes. Various customizable options ensure proper fittings for various needs and effective cleaning.

Running tube cleaning brushes through the tubes or pipes regularly prevent blockages and ensure smooth liquid or gas flow. These brushes prevent obstructions due to accumulated debris, reducing efficiency, increasing maintenance costs, and possibly causing system failure.

Extends the Life of a System

These also aid in giving the general life to the systems they are used in. Tube cleaning brushes also help prevent corrosion, wear, and other deteriorations that might cut down the life of the pipes and tubes through constant maintenance.

The many reasons tube cleaning brushes are great include the deep cleaning they provide, versatility in application, block nothing, remain easy to use, and increased longevity for whatever system is set up.

Cleaning tube brushes, for these reasons, are indispensable for the smooth running of every other system. Be it an industrial, laboratory, or commercial environment, tube cleaning brushes will ensure that everything runs smoothly and that expensive machinery is preserved for as long as possible.

Tube Cleaning Brushes – The Ultimate Guide To Choose The Right Brush Consider Top Factors While Choosing Tube Cleaning Brushes

/0 Comments/in Blog, File /by BolexbrushThe Ultimate Guide To Choose The Right Brush Consider Top Factors While Choosing Tube Cleaning Brushes

It is a challenge to clean and maintain cleanliness at narrow, difficult-to-reach surfaces. Whether you need to clean straws, bottles, pipes, or intricate machinery parts, selecting the right tube cleaning brush is crucial for efficiency and effectiveness. This ultimate guide will make you understand the key considerations to help you choose the perfect tube cleaning brush for your needs.

The Tube cleaning brushes are one of the most popular cleaning brushes available today and come in various shapes and sizes to provide maximum results to the users. You have to consider various factors while choosing this brush including the handle and brush head, and the material quality.

Considering handle and brush head design

Comfort and Reach – Choose a handle length that provides comfortable grip and sufficient reach for the tubes you need to clean.

Material – Handles can be made of plastic, metal, or wood. All type of material provides some type of benefits to the users of these brushes.

Considering the brush head design

Straight vs. curved – Straight brush heads are suitable for linear tubes, while curved or angled brush heads can reach around bends and corners more effectively.

Size – Ensure the brush head is appropriately sized for the tube’s diameter. A brush that is too small won’t clean effectively, while one that is too large may not fit or may get stuck.

Application of this brush in different industries

Food and beverage industry

For cleaning straws, bottles, and other food-related tubes, opt for nylon bristles due to their gentle yet effective cleaning properties. Ensure the brushes are labeled food-safe and resistant to common cleaning agents used in kitchens.

Industrial and mechanical cleaning

When dealing with industrial machinery, pipes, or automotive parts, stainless steel bristles are often the best choice. Their durability and abrasive power can handle tough grime and residue. For sensitive equipment, brass bristles might be more suitable.

Medical and laboratory equipment

Cleaning medical and laboratory equipment requires brushes that can ensure thorough cleaning without causing damage as they are gentle on the surface.

Home and DIY projects

For everyday home use, such as cleaning reusable straws, aquarium tubes, and small household appliances, nylon brushes are versatile and safe. Consider sets with multiple sizes to cover various tasks around the house.

Tips for choosing the right brush

- Measure your tubes –Know the inner diameter and length of the tubes you need to clean to select the appropriately sized brush.

- Consider the cleaning environment –Choose bristle materials and handle types that are compatible with the substances and conditions they will be exposed to.

- Buy quality –Invest in high-quality brushes from reputable manufacturers to ensure longevity and effective cleaning.

Conclusion

Selecting the right Tube Cleaning Brushes involves understanding your specific cleaning needs and matching them with the appropriate bristle material, handle design, and brush head type. By considering these factors, you can ensure that your cleaning tasks are performed efficiently and effectively, maintaining the cleanliness and functionality of your tubes and equipment.

What Makes Tube Cleaning Brushes Popular?

/0 Comments/in Blog /by BolexbrushIn the intricate landscape of industrial maintenance, there exists a tool often overlooked yet indispensable: the tube cleaning brush.

Precision in Purification

Tubes and pipes form the arteries of many industries, channeling fluids and gases vital for operations. However, over time, these conduits can fall victim to debris buildup, scale deposits, and other contaminants, impeding flow and efficiency. Explore tube cleaning brushes, adept at delving deep into tubes, dislodging impurities, and restoring optimal functionality.

Versatility Across Industries

The versatility of tube cleaning brushes transcends sectors, proving indispensable in diverse applications. Whether it’s eradicating corrosion in heat exchanger tubes or clearing condensate drains in HVAC systems, these brushes are the unsung heroes of maintenance. They excel in cleansing boiler tubes in power plants, sanitation pipes in food processing facilities, and intricate medical equipment tubing.

Tailored Solutions

Recognizing that one size rarely fits all, custom tube cleaning brushes offer tailored solutions to unique challenges. By adjusting parameters such as diameter, length, and bristle material, these bespoke brushes ensure precise cleaning, maximizing efficiency and effectiveness.

Regular maintenance, facilitated by tube cleaning brushes, is the linchpin of operational efficiency. By preventing the accumulation of debris and obstructions, these brushes minimize downtime, boost energy efficiency, and prolong equipment lifespan. The investment in periodic brush replacement is dwarfed by the potential costs of system failures and repairs resulting from neglect.

Championing Sustainability

By optimizing system efficiency, the brushes reduce energy consumption and carbon emissions, aligning with sustainability goals. Moreover, their durable construction minimizes waste, underscoring their role as sustainable solutions for conscientious industries.

The tube cleaning brushes may seem unassuming, but their impact is far-reaching. From enhancing operational efficiency to championing sustainability, these modest tools wield significant influence in maintenance practices across industries. Embracing their potential not only ensures smoother operations but also advances the journey toward a cleaner, more sustainable future.

How Beneficial The Strip Brushes Can Be?

/0 Comments/in Blog /by BolexbrushIn the expansive world of industrial and commercial sectors, innovation often arises from the most basic tools. Unique strip brushes, an evolution from traditional designs, boast numerous advantages that distinguish them across industries.

Innovative strip brushes integrate advanced materials and designs to deliver superior performance compared to their traditional counterparts. Whether through specialized bristles tailored for specific tasks or innovative backing materials for heightened durability, these brushes excel in demanding environments where precision and reliability are crucial.

From customized bristle configurations to specialized backing materials, manufacturers collaborate with clients to create brushes optimized for their specific requirements, resulting in optimized performance and efficiency.

Versatility Across Applications

Thanks to their customizable features and advanced design elements, unique strip brushes find application across a broad spectrum of industries. Whether it involves sealing solutions in aerospace, conveyor belt cleaning in manufacturing, or surface finishing in automotive, these brushes adapt seamlessly to various tasks and environments, showcasing their versatility and utility.

Improved Efficiency and Productivity

By leveraging innovative materials, designs, and configurations, unique strip brushes enhance efficiency and productivity in industrial processes. Whether it’s by reducing downtime through minimized equipment maintenance or enhancing product quality with precise sealing and cleaning, these brushes contribute to streamlined operations and increased output.

Embracing Environmental Sustainability

In an age where sustainability is increasingly valued, unique strip brushes stand out for their eco-conscious features. Through the use of recyclable materials, minimizing waste during production, and promotion of energy-efficient processes, manufacturers of these brushes align with sustainable practices, appealing to environmentally conscious industries and consumers.

Despite their advanced features and tailored designs, unique strip brushes offer cost-effective solutions for a variety of applications. By improving operational efficiency, lowering maintenance costs, and enhancing product quality, these brushes provide long-term value, making them a prudent investment for businesses seeking to optimize their processes.

The unique strip brushes represent a leap forward in brush technology, offering a multitude of benefits across industries. From enhanced performance and customized solutions to versatility, efficiency, sustainability, and cost-effectiveness, these innovative brushes set new standards for excellence in industrial applications. As industries evolve, the adaptability and versatility of unique strip brushes ensure they remain indispensable tools in the pursuit of efficiency and productivity.

What Makes Twisted In Wire Brush Popular?

/1 Comment/in Blog, News /by BolexbrushIn the industrial realm of maintenance and surface preparation, the twisted-in-wire brush emerges as a versatile and indispensable tool. From intricate cleaning tasks to surface refinement and deburring, these brushes fulfill a broad range of roles across diverse industries.

Twisted in wire brush, also known as spiral brushes, feature bristles that tightly encircle a central wire stem. This unique design creates a dense and resilient brushing surface, capable of enduring rigorous use in demanding industrial environments. The bristles can be crafted from various materials, including steel, stainless steel, brass, nylon, and abrasive filaments, providing tailored solutions for specific applications.

Learn More About The Brushes For Better Understanding

The versatility of twisted in wire brush extends across industries such as manufacturing, automotive, aerospace, construction, and metalworking. Whether it’s removing rust and corrosion, cleansing machinery and equipment, smoothing metal surfaces, or refining intricate parts, these brushes prove invaluable across a multitude of tasks.

Offering a range of benefits, including precision cleaning, durability, customization options, and adaptability, twisted-in-wire brushes stand out. Their tightly packed bristles ensure meticulous cleaning even in complex areas, without compromising the underlying surface. Constructed from robust materials and designed for longevity, these brushes withstand harsh conditions, reducing the need for frequent replacements. Moreover, their flexibility in size, shape, bristle material, and density allows for tailored solutions to meet specific needs, ensuring optimal performance across various industrial tasks.

In practical terms, twisted-in-wire brushes find utility in metalworking processes, aiding in deburring, cleaning, and surface preparation. They effectively eliminate burrs, rust, and scale from metal surfaces, guaranteeing smooth finishes and precise machining. In welding applications, these brushes facilitate clean weld seams, spatter removal, and surface preparation, ensuring the integrity of welds. Additionally, in machinery maintenance, twisted-in-wire brushes contribute to cleaning and lubricating moving parts, removing accumulated debris, and sustaining equipment performance and longevity.

Twisted-in-wire brushes represent versatile tools with a multitude of applications in industrial settings. Their distinctive design, durability, customization options, and adaptability render them indispensable across various industries. Whether it’s precision cleaning, deburring, or surface refinement, twisted-in-wire brushes offer efficient and cost-effective solutions for diverse industrial tasks, making them an invaluable addition to any toolkit.

Latest Products

Latest News

Product Category

Contact Us

Phone:008618613144964

Email: [email protected]

ADD:NO.1 GONGYE ROAD ,CONGHUA ECONOMIC DEVELOPMENT ZONE,TAIPING TOWN,CONGHUA DISTRICT,GUANGZHOU ,CHINA

Bolexbrush

Bolexbrush