Tube Cleaning Brushes – The Ultimate Guide To Choose The Right Brush Consider Top Factors While Choosing Tube Cleaning Brushes

The Ultimate Guide To Choose The Right Brush Consider Top Factors While Choosing Tube Cleaning Brushes

It is a challenge to clean and maintain cleanliness at narrow, difficult-to-reach surfaces. Whether you need to clean straws, bottles, pipes, or intricate machinery parts, selecting the right tube cleaning brush is crucial for efficiency and effectiveness. This ultimate guide will make you understand the key considerations to help you choose the perfect tube cleaning brush for your needs.

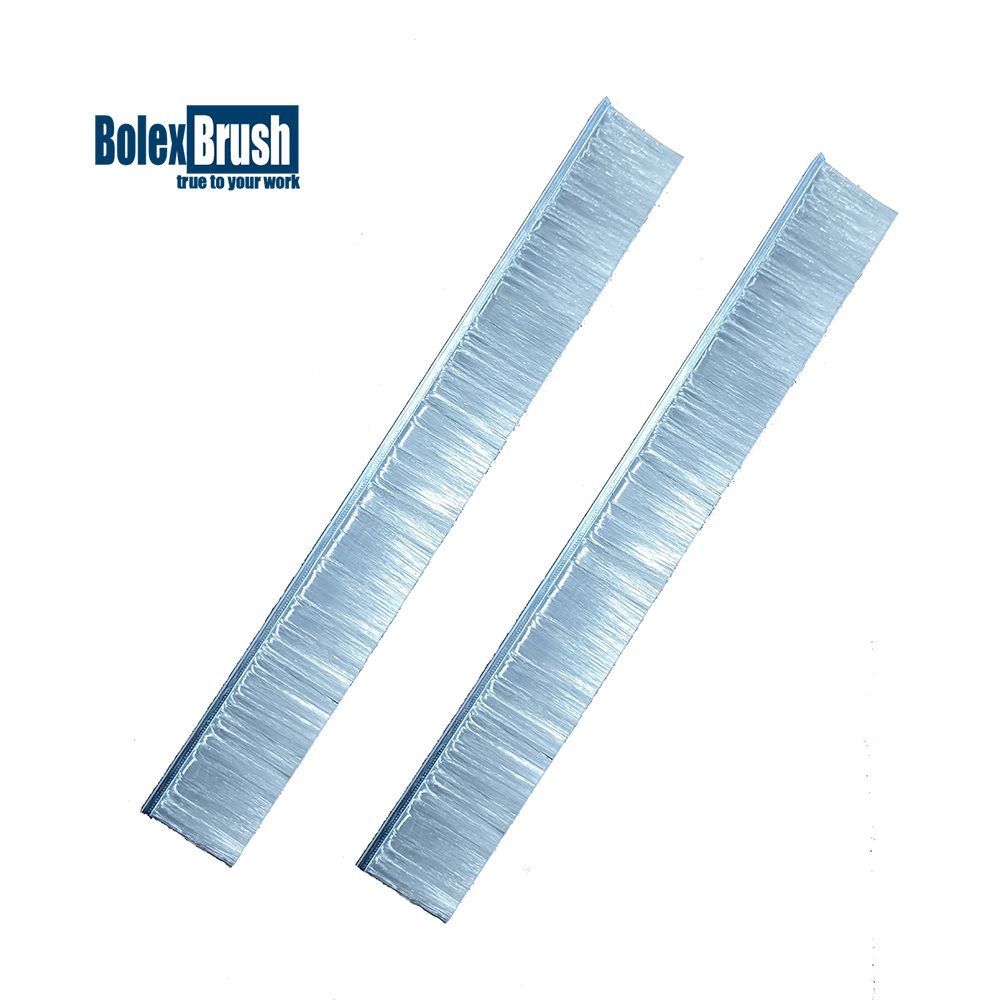

The Tube cleaning brushes are one of the most popular cleaning brushes available today and come in various shapes and sizes to provide maximum results to the users. You have to consider various factors while choosing this brush including the handle and brush head, and the material quality.

Considering handle and brush head design

Comfort and Reach – Choose a handle length that provides comfortable grip and sufficient reach for the tubes you need to clean.

Material – Handles can be made of plastic, metal, or wood. All type of material provides some type of benefits to the users of these brushes.

Considering the brush head design

Straight vs. curved – Straight brush heads are suitable for linear tubes, while curved or angled brush heads can reach around bends and corners more effectively.

Size – Ensure the brush head is appropriately sized for the tube’s diameter. A brush that is too small won’t clean effectively, while one that is too large may not fit or may get stuck.

Application of this brush in different industries

Food and beverage industry

For cleaning straws, bottles, and other food-related tubes, opt for nylon bristles due to their gentle yet effective cleaning properties. Ensure the brushes are labeled food-safe and resistant to common cleaning agents used in kitchens.

Industrial and mechanical cleaning

When dealing with industrial machinery, pipes, or automotive parts, stainless steel bristles are often the best choice. Their durability and abrasive power can handle tough grime and residue. For sensitive equipment, brass bristles might be more suitable.

Medical and laboratory equipment

Cleaning medical and laboratory equipment requires brushes that can ensure thorough cleaning without causing damage as they are gentle on the surface.

Home and DIY projects

For everyday home use, such as cleaning reusable straws, aquarium tubes, and small household appliances, nylon brushes are versatile and safe. Consider sets with multiple sizes to cover various tasks around the house.

Tips for choosing the right brush

- Measure your tubes –Know the inner diameter and length of the tubes you need to clean to select the appropriately sized brush.

- Consider the cleaning environment –Choose bristle materials and handle types that are compatible with the substances and conditions they will be exposed to.

- Buy quality –Invest in high-quality brushes from reputable manufacturers to ensure longevity and effective cleaning.

Conclusion

Selecting the right Tube Cleaning Brushes involves understanding your specific cleaning needs and matching them with the appropriate bristle material, handle design, and brush head type. By considering these factors, you can ensure that your cleaning tasks are performed efficiently and effectively, maintaining the cleanliness and functionality of your tubes and equipment.