Strip Brushes for the Most Amazing Experience

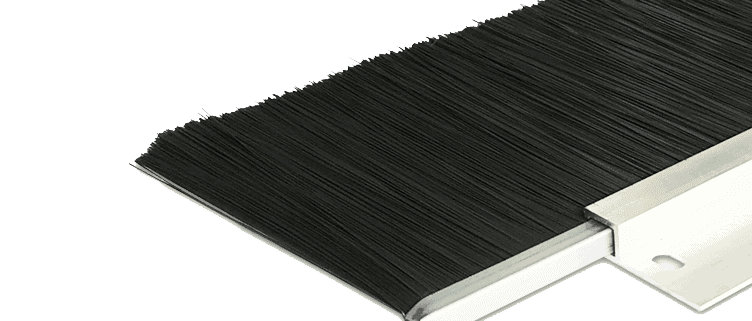

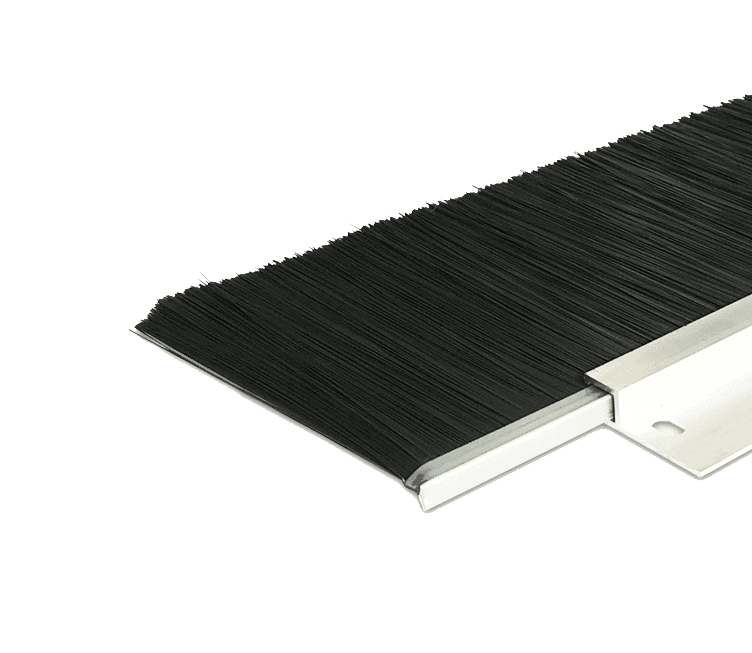

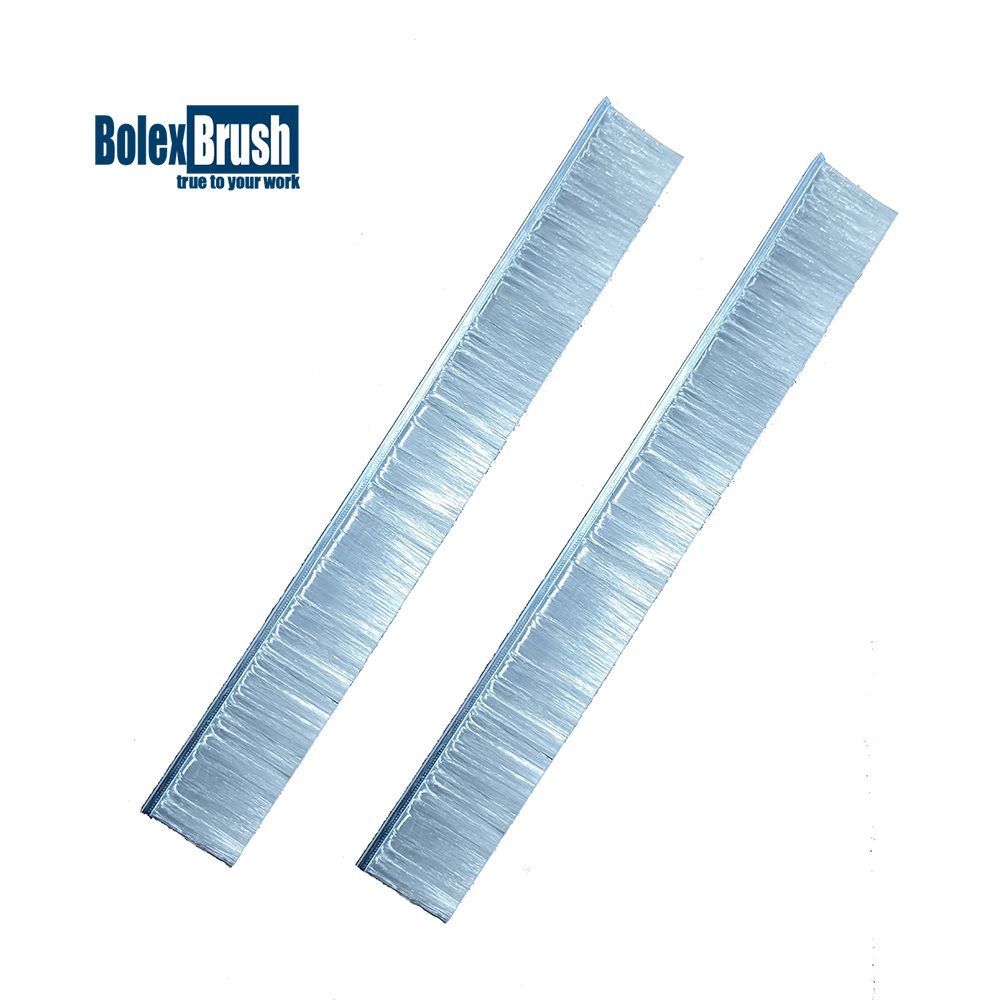

Strip brushes are very effective but straightforward tools that find application across various industries to seal, clean, protect, and guide operations. They are bristles rigidly attached to a metal, plastic, or wooden channel. Strip brushes can be tailored in size, shape, and filament material to suit specific requirements. Strip brushes are valuable components in manufacturing, construction, transportation, and trade machinery due to the fact that they are versatile, robust, and cost-efficient.

Sealing is also among strip brushes major applications—particularly on equipment, doors, conveyor lines, and automated machinery. Placed along cracks or working surfaces, they act as malleable barriers to prevent intrusion by dust, dirt, air flows, humidity, and bugs. Where there is a need for hygiene—food plants, clean rooms, or pharmaceutical factories strip brushes seal out invasions of contaminants by offering sealed and clean work conditions.

The strip brushes

Aside from sealing, strip brushes are also used for surface cleaning and material guiding. On conveyor belts, they clean out particles or trash from product surfaces. In machine manufacturers, they guide oncoming parts or materials without scratching or damaging them. Their firm but flexible bristles are able to adapt to irregular surfaces and maintain steady contact without distorting or losing effectiveness.

The ability of strip brushes to hold dust, dirt, and grime for specific work increases their popularity. Bristles may be nylon, polypropylene, or natural bristles, or stainless steel or brass, depending on work to be performed. Brushes are either light-duty dusting tools or heavy-duty scrubbers and abrasives. Strip brushes can be designed in spiral coils, curved bends, or circular bends to handle more intricate tasks.

Strip brushes are also available in retail and commercial applications—on loading docks, escalators, display cabinets, or door bottom to control airflow, reduce noise, or for safety. Simple installation and maintenance through streamlined design renders them a cheap, long-term solution with little downtime.

Strip brushes are all-purpose equipment that offers uniform sealing, cleaning, and protection in many sectors. Their long lifespan, flexibility, and adaptability make them an intelligent decision for ensuring maximum performance, efficiency, and safety in different mechanical and operational systems.