The famous and great strip brushes

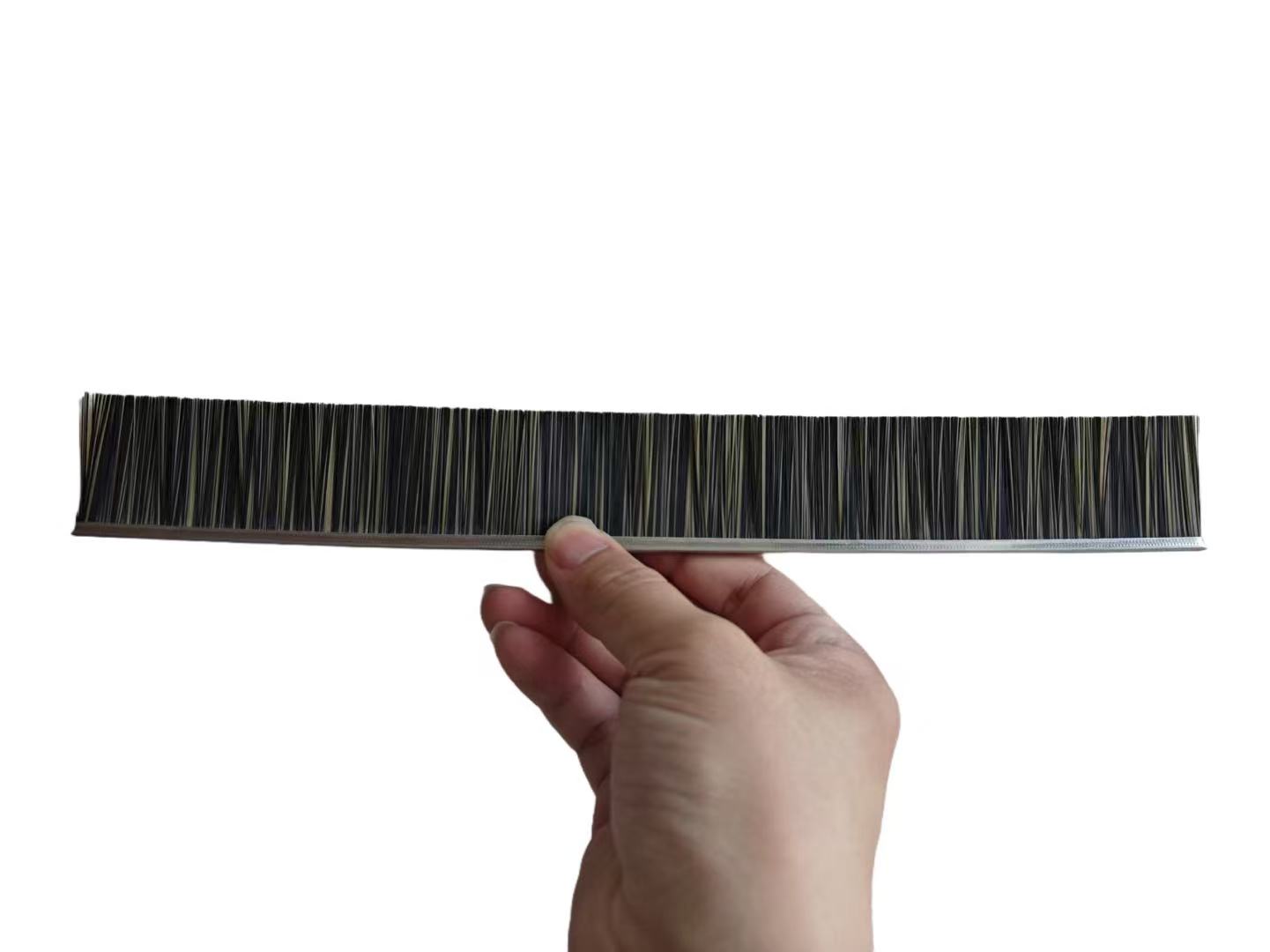

Strip brushes are so simple, yet their applications cross industries with continuous performance in sealing, guarding, cleaning, and static control. The linear brushes consist of bristles welded between a fixed metal strip, creating a lasting and durable solution for general mechanical and maintenance purposes.

The valuable strip brushes

Strip brushes are among the significant advantages of working as closure devices. Strip brushes are air, dust, light, and even insect barriers in rolling shutters, conveyor belts, windows, and doors. Their closely arranged bristles are just as useful for uneven surfaces as for moving surfaces and provide insulation and effectiveness. They are active seals on machines and equipment in industries and force waste away from delicate pieces, leaving the work area clean.

In addition to sealing, strip brushes are also used heavily in conveyor cleaning and material handling systems. The steady rubbing action does not allow belts and surfaces to create residue, stopping jamming and wear potential. At packaging lines, textile mills, or food processing plants, strip brushes provide smoother operation and reduced downtime.

Their applications also involve electrostatic discharge (ESD) protection and light blocking. In the production of electronics and in laboratory settings, there are unique anti-static strip brushes that ensure static charge is not built up, protecting against vulnerable circuitry. In photocopiers, scanners, and imaging equipment, the brushes are used to control the flow of light and smooth functioning.

One of the factors that make them successful is personalization. Strip brushes are produced in various lengths, filament types, and densities to match specific requirements. They can be mounted on metal strips or integrated into automated equipment with adjustable options for repetitive tasks.

Strip brushes are low-profile performers across a variety of applications. Easy to design but powerful in performance—keeping surfaces clean, effective, and protecting in commercial and industrial applications. In their extended lifespan, flexibility, and low-maintenance nature, they are an investment to be taken for any building that demands consistent sealing or brushing performance.

Leave a Reply

Want to join the discussion?Feel free to contribute!